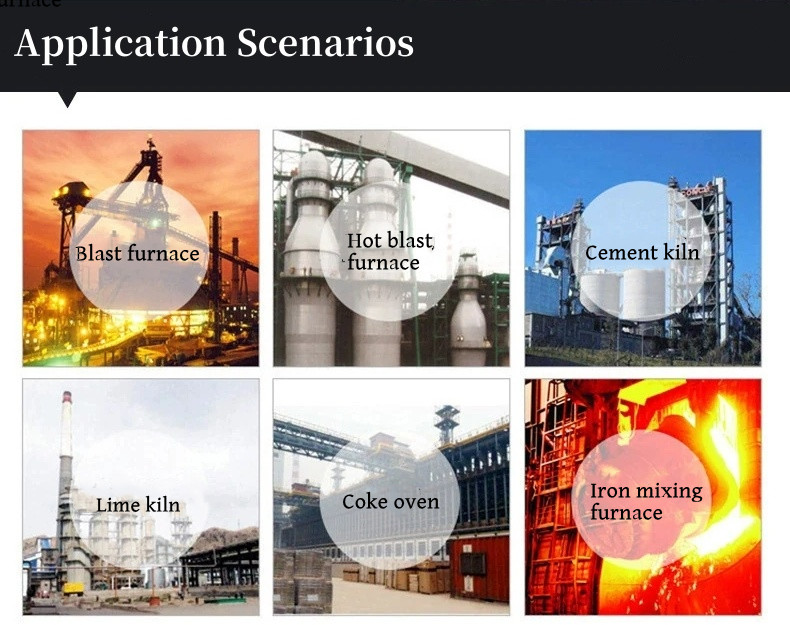

industry, non-ferrous metal furnaces and thermal power plants. They are suitable for high temperature and chemical exposure areas.

| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations